Material

Generally, what kind of material do we want to use to build our trimaran?

Wood

We love wood and we wouldn't consider any other material. First, I have a lot of experience with wood, as cabinet maker and from building ALCEDO. Wood is a very versatile and sustainable material.

The first plan was to use plywood as in our first project. It is a stabilized material and very easy to work with, e.g. bending, cold molding and so on.... Plywood has good specifications and is fast/easy to build from. Not to mention minimum of sanding and fairing needed before topcoats. With Cristian we set the direction to go with plywood as main building material.

Parallel to the work on the design, I did market research on plywood. I was shocked, how the prices evolved in the last few years compared to our first project.

Immediately, we contacted our designer to find a more reasonable way for building. So, we agreed on the solid wood speed strip plank method. Yes, some can say it is going from one expensive solution to another expensive solution, or as Germans would say "vom Regen in die Traufe" (out of the frying pan and into the fire). But since I have a well equipped workshop, we are able to fabricate planks by ourselves, which makes minimum half of the production cost. Another advantage of strip planking is the unlimited possibilities of refining the shape and curves to perfection. We are sorry Cristian, you will have to redesign the hard-chain plywood construction to speed strip planking. We are very sorry.

|

|

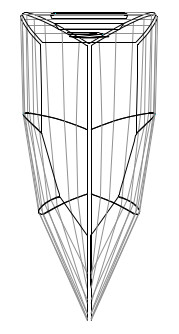

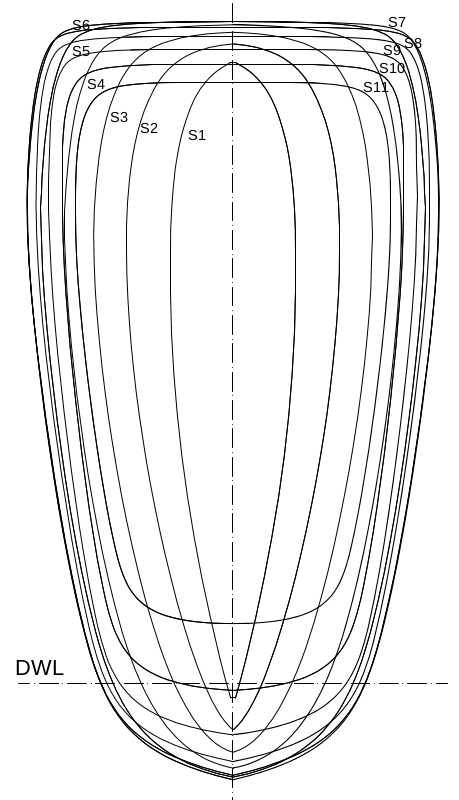

| Hard-Chine (left) vs. Speed strip planking (right) | |

The next question was, which type of wood we would use for the planks.

First choice is always Western redcedar. It is a worldwide well known material for boat building. Because we live in Europe, western redcedar is considered an exotic wood and the price per cubic is "exotic" too. So NO. Again. Second choice: Weymouth pine, Eastern White Pine (Pinus Strobus). I watched an old northern American boat builder who recommended it as a very good material for boat building. Weymouth pine can be sourced in Europe as a domestic wood. Again we checked the market. Kerstin send multiple emails and phone calls for a reasonable supplier in Germany. The best offer we got was "Yes we can get a whole log for you, but we can not guarantee the quality." For us the wood quality is a very important aspect. The best option is A and the lowest we would use is B. We wouldn't consider C at all. You know, to take a risk and to end up with a large amount of wood good enough to build a bee hive, which is a common use for Weymouth pine, was not acceptable. So again, back to square one on researching alternative wood. This time I took the list of wood available on the market and went with the exclusion method. Few boxes have to be ticked: weight, elasticity, work-ability (bending...), sustainability and of course price.

What was left? Not much. What catched my eye was Okoumé/Gaboon. Since I know that most of the standard marine plywood is made out of Okoumé veneer anyway. After discussion with Cristian a decision was made for Okoumé... Some might say, Okoumé doesn't have the best rot resistance. This box we can ignore, since most of the parts of the boat will be laminated over, inside and outside, at least with one layer of fiberglass.

We made a very good deal for a selection of A quality Okoumé for the price of a bit more than European spruce on the German market. Hurrah, we got wood...

|

|

| Sailplan | Building Schedule |